CIC Zero Carbon Park (CIC ZCP)

Hong Kong

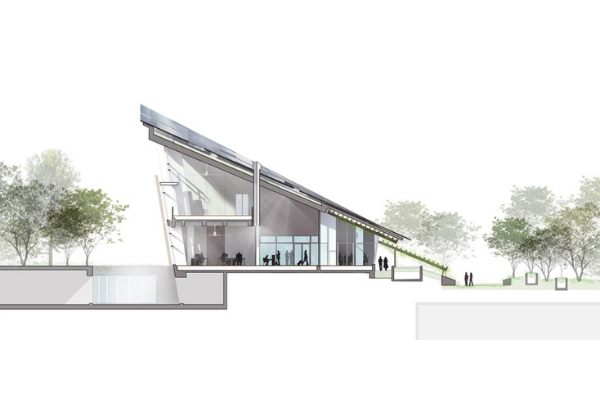

Daylight and Orientation

The glazing on NW facade is oriented towards the unobstructed sky providing ample light while sheltering from direct sunlight or glare. Light shelves provided on the SE and NW façade shade the periphery of the building and distribute the daylight deeper into the space. Light pipes capture the light from the domes of the roof. These highly reflective tubes provide light in spaces devoid of fenestrations. External glass walls are shaded as per different solar conditions on each orientation by external shades.

Ventilation

The main façade faces southeast to optimise prevailing summer winds – a perfect strategy for combating Hong Kong’s humid weather conditions. The building is equipped with two wind catchers on the roof. The higher wind velocity at the roof level forces the air down the shaft and cools the building.

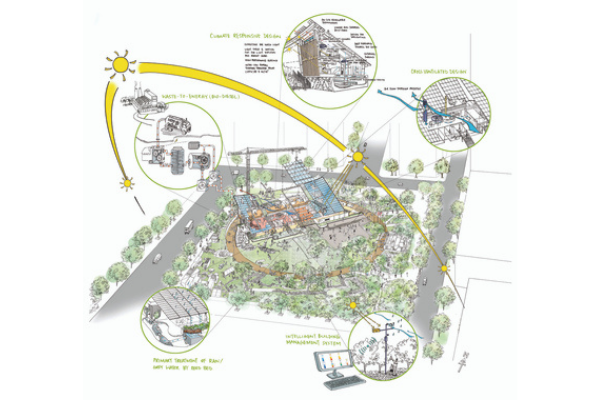

Landscaping and Water Efficiency

Nearly 47% of the site is green which significantly reduces the ambient air temperature.

The planted urban native woodland area of approximately 2000 m2 includes 135 native trees of over 40 different species and a diversity of native shrubs, providing food and shelter to attract native wildlife to the city.

A green wall at the entrance resists strong winds and provides thermal insulation.

Rainwater from the sloped roof drips towards a constructed wetland which filters the water through the roots of plants before passing to the recycled water system. A drip Irrigation system distributes water directly to soil to minimize water wastage.

A 180 m3 rainwater storage tank is installed to store rainwater processed from the constructed wetland. This water is used in the landscaped area for irrigation.

Thermal Insulation

An earth cooling tube provides naturally pre-cooled air to reduce the cooling load and energy use in the hotter months when the mechanical cooling system is operating continuously.

The roof is covered with cellular glass insulation, screeding, and a protective surface membrane. About 85% of the roof area is covered with photovoltaic panels while the rest is green roof.

Movable aluminium heat reflecting shades fitted behind the glazing around the exhibition hall reflect, absorb, and emit the radiant heat while diffusing the light.

The high-performance glass wall system offers good thermal and lighting performance to lower cooling load. Daylighting reduces dependence on artificial lighting and energy consumption.