Cooling accounts for almost 50% (or more) of the energy consumption in commercial buildings. Further, refrigerants used in conventional HVAC systems are often ozone depleting substances that are also greenhouse gases. Thus, low energy cooling solutions using environment friendly refrigerants are essential for achieving energy efficiency while providing comfort. This approach is essential for NZEBs.

This webinar discusses one such low energy cooling technology as an alternative to conventional electric chillers – Vapor Absorption Machines (VAM). Mr. Vaidyanathan from Thermax, walks us through the working principle and application of VAMs along with insightful case studies.

Just like a conventional vapor compression-based HVAC system, VAM consists of evaporator, condenser and a thermal compressor. The difference is that instead of the compressor, we have an absorber. There are two combinations of ‘refrigerant:absorber’ that are used – ‘demineralized water:Lithium Bromide (Li-Br) solution’ and ‘ammonia:water’.

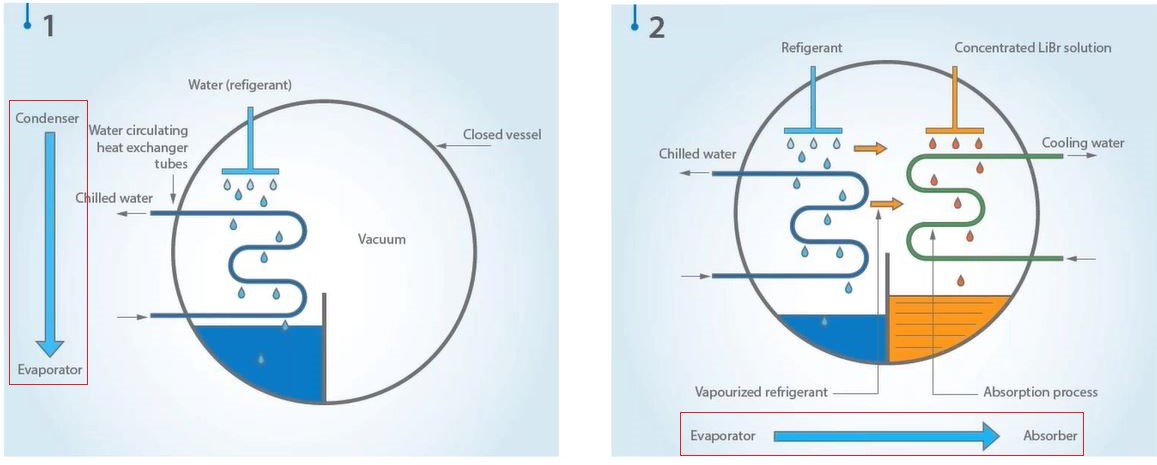

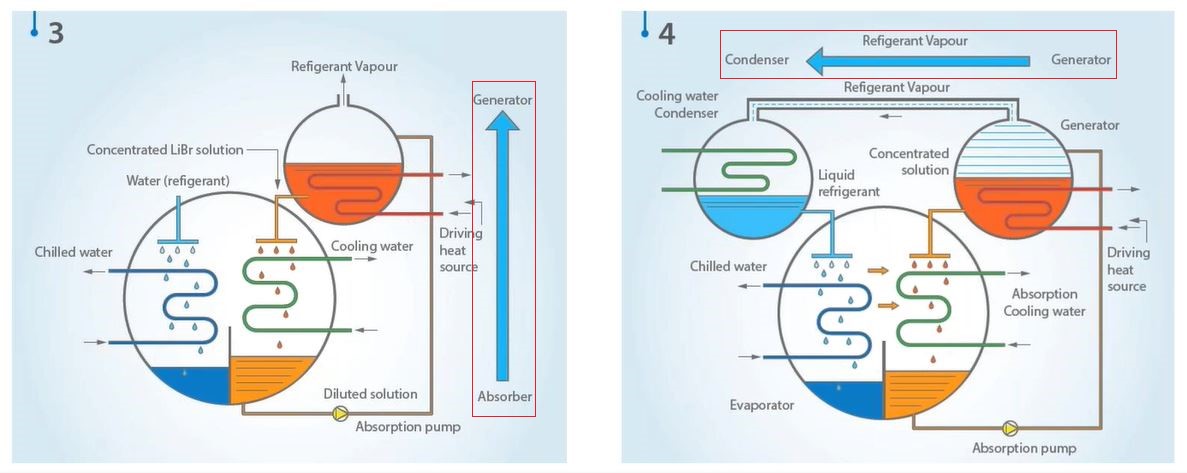

The vapor absorption technology relies on 2 properties of fluids:

- Evaporation and cooling at low temperatures in low pressure/vacuum environment

- Hygroscopy of materials

Let’s now look at the working mechanism. Cooled refrigerant (demineralised water) is introduced into the evaporator which is maintained at very low pressure/vacuum. It absorbs the heat from the chilled water supply of the HVAC system and evaporates. These vapors are absorbed by the concentrated absorber (Li-Br solution), thereby maintaining the pressure levels in the chamber. The heat that is released from the conversion of vapor to liquid is absorbed by the cooling water pipes that is connected to the cooling tower.

This diluted absorber solution is then pumped to the generator where it is heated using the driving heat source. This leads to the evaporation of the refrigerant (in this case water) vapors which flows towards the condenser. There, the vapor is condensed back to liquid and the cycle repeats.

A vapor absorption machine (VAM) utilizes this principle along with heat recovery for cooling in a HVAC system. Heat Recovery is the utilization of waste heat energy for the heating purposes of the system. This energy utilization improves the efficiency of the system

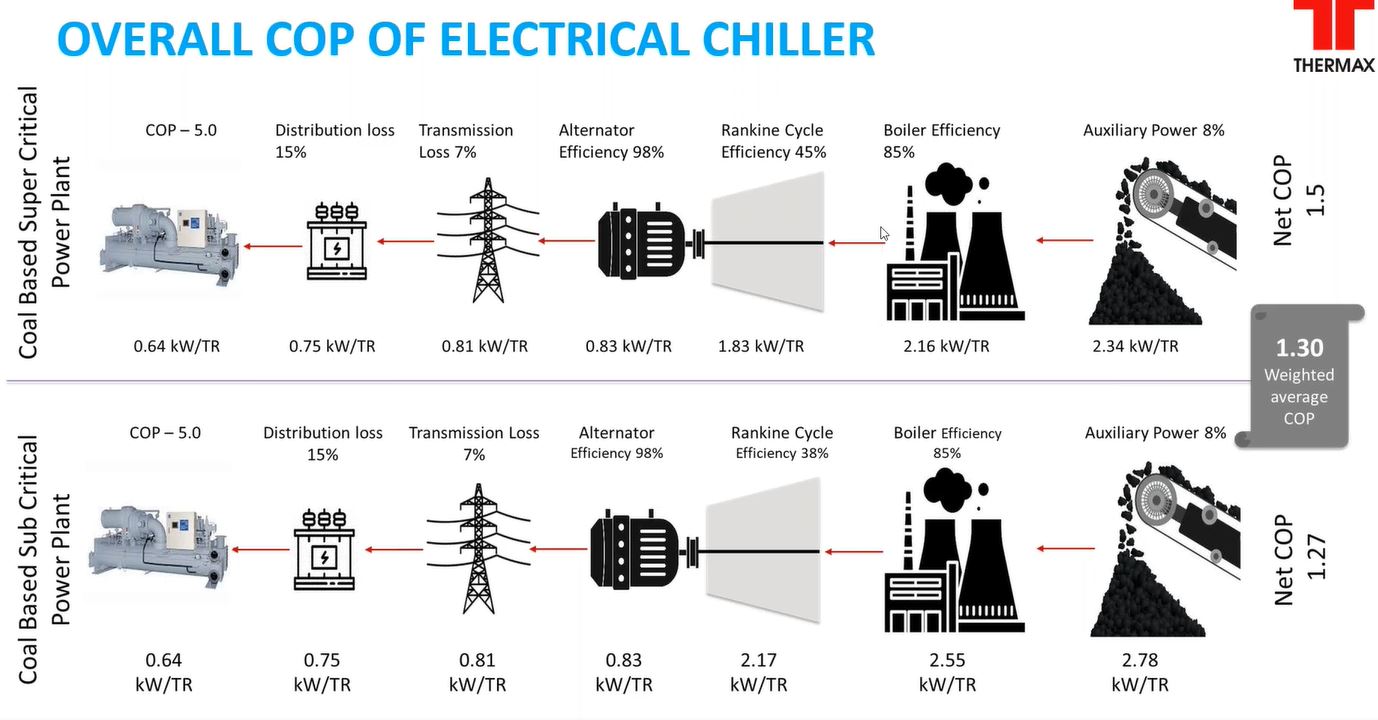

The reason why vapor absorption machines (VAM) are more energy efficient than the vapor compression refrigeration machines can be mainly contributed to:

- Utilization of heat recovery for the heating processes

- Power consumption of the pumps used in VAM being around 1/10th as that of the motors in the compression cycle.

The overall performance of VAM is best understood in the context of ‘net COP’ when compared to electrical chiller. The net COP of electrical chiller, which is a measure of the cooling load generated for the source energy input, is around 1.3, while it is around 1.5 for VAM. Using a natural refrigerant with 0 ozone depleting potential (ODP) and global warming potential (GWP) in this technology, we have a cooling system which is energy efficient and more sustainable.

VAMs can be classified on the basis of the heat recovery mechanism used. The different types of VAMs are:

- Water driven vapor absorption chiller: This chiller uses the hot water as its heat driving fuel. It has a COP of 0.8 and is usually used for smaller cooling capacities.

- Direct fired absorption chiller: This is the most commonly used VAM. It is usually found in commercial establishments like hotels, hospitals, malls, etc. Fuels like Natural gas, LPG, propane, etc. are used as sources of heat. This system typically has a COP of 1.5.

- Exhaust gas driven absorption chiller: This VAM utilizes the heat from the exhaust gases. It has a COP of about 1.5 and is used for capacities as high as 3500 TR.

- Multi Energy Absorption Chiller: This VAM can utilise the heat from multiple sources like exhaust gas, hot water or even a combination of both.

Although VAM has a lower COP than an electric chiller, it has several advantages:

- Works with any thermal source and is not reliant on electrical sources.

- Utilizes heat recovery for better efficiency.

- Less power requirements for pumps.

- Lesser moving parts which translates to quiet operation and no vibration.

- Less maintenance costs.

- Has a higher net COP than electric chillers (heat source to cooling energy)

- Can work on lower loads without affecting COP.

- Natural refrigerants which have 0 ODP and GWP.

Considering its advantages, VAM is being considered as a viable alternative to conventional electric chillers. Several examples for applications have been discussed in the webinar.

This webinar was conducted on 15th November, 2019