The Centre for Advanced Research in Building Science and Energy (CARBSE) in CEPT University, Ahmedabad houses some of the world’s most cutting-edge research in energy-efficient building design. At the same time, it’s a living laboratory in itself, operating as a net-zero energy building. As a result, the building provides invaluable lessons in designing, constructing and operating a net-zero energy facility.

This webinar brings on board two experts from CARBSE, Prof. Rajan Rawal – Executive Director and Dr. Yash Shukla – Technical Head. They bring their expert insights and rich experience of designing, occupying and managing an exemplary Net Zero Energy Building in India.

CARBSE was conceived as an exemplar of net-zero energy design strategies and technologies specific to the Indian climate. The model NZEB would thus be the perfect setting to conduct research on high-performance building design, tech and policy.

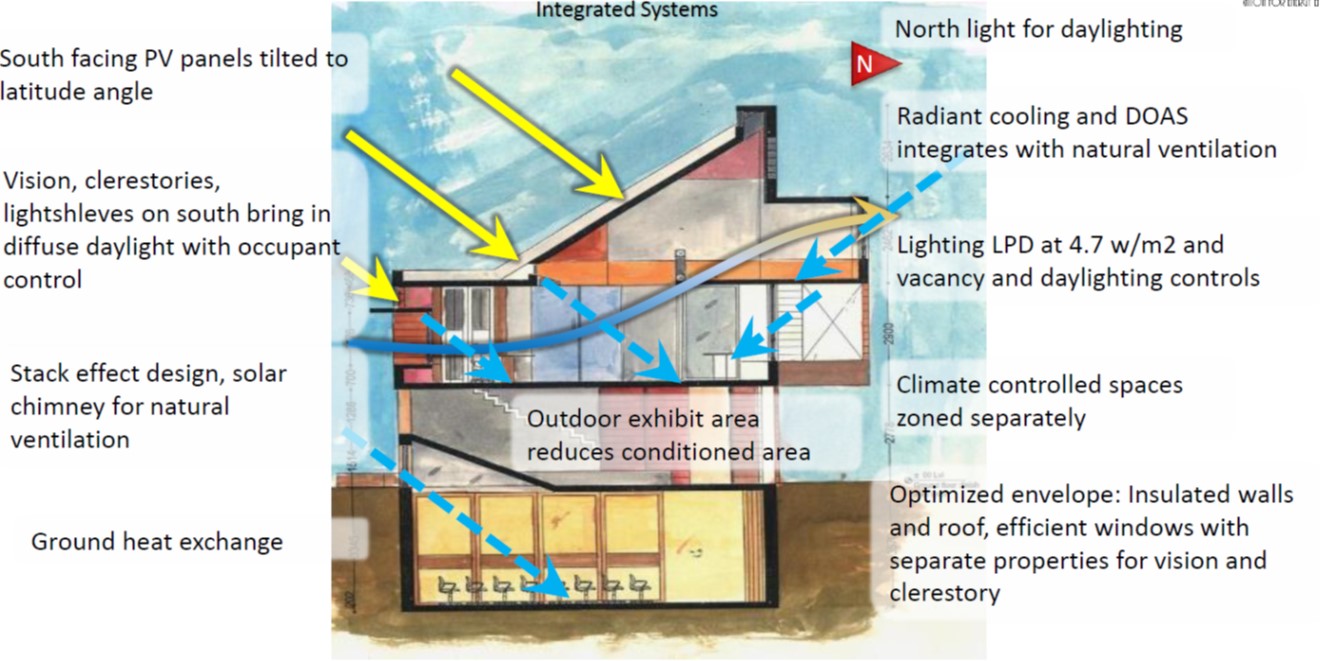

The team was committed to an integrated design approach to maximize synergies across disciplines and expertise. Through an iterative process, the team arrived at an Energy Performance Index (EPI) target at 58 kWh/sqm/yr for CARBSE. Various passive and active measures were integrated into the building design to achieve the ambitious EPI target. Let us take a closer look at these measures.

Firstly, the building was oriented towards the South with a sloping roof to accommondate the solar PV. Next, the team analyzed several massing options for the arrive at the design with the least heat loads and corresponding energy consumption.Building envelope optimization ensured further reduce heat ingress. The façade with thermal mass and insulation offer high thermal resistance and lag during hotter months. The low-e double glazing unit with a Visual Light Transmittance (VLT) of 39% ensures optimum daylighting without heat gain. Clearstory windows with a VLT of 33% provide glare-free north lighting. Light shelves reflect daylight deeper inside the workspace. Occupancy controls and daylight sensors enable a Lighting Power Density (LPD) at 4.7 W/sqm.

A mixed mode space conditioning system has been designed for CARBSE. For example, the basement uses a VRF system while the ground floor is naturally ventilated. The first floor and mezzanine can switch between mechanical and natural modes. Space cooling is also provided by a radiant system. Ventilation requirements are met through natural ventilation as well as a dedicated outdoor air system (DOAS).

Dr. Yash shares several practical insights into ensuring CARBSE’s NZE status through the years. We learn that CARBSE is intensively monitored all year, equiped with 1000 control points to monitor indoor environment, envelope, energy consumption, occupant comfort, equipment end-use, etc hrough a state-of-the art Building Management System (BMS) system. The data is displayed on an LCD screen in real-time. Components like energy meters, photovoltaics and chillers can be easily integrated with the BMS as they come pre-fitted with sensors and controls, and only need a communication gateway. However, for components like lighting, DOAS and fans, the team had to install sensors and controls before integrating it with the BMS system.

The experts shared monitored data of 2016-17 where HVAC energy use was 24.1 kWh/sq.m/yr followed by research equipments consuming around 15.5 kWh/sq.m/yr. Plug loads were very low at 2.7 kWh/sqm/yr while the daylighting strategies were succesful in reducing the lighting energy merely 0.1 kWh/sq.m/yr. In that year, CARBSE was energy positive with consumption is at 42.5 kWh/sq.m and generation at 51.2 kWh/sq.m

Monitored data shows that the indoor temperatures are within the 80% and 90% acceptibility limit as per the Indian Model of Adaptive Comfort (IMAC) model indicating that it is possibe to acheive thermal comfort standards while reducing the energy use. Further, thermal comfort is also assessed through weekly surveys for qualitative feedback from occupants.

To summarize, CARBSE shows that climate responsive design strategies can help achieve comfort with less energy use. The data clearly demonstrates that occupants feel comfortable in the temperature range as per the IMAC criteria. This approach alongwith passive strategies and efficient mechanical systems has sharply reduced the energy demand which is met with rooftop solar PV systems making this a ‘high-performance NZEB’. It underscores the need for continuous monitoring and measurement to maintain the net-zero energy goal.

This webinar was conducted on 23 July 2019.