Central air conditioner

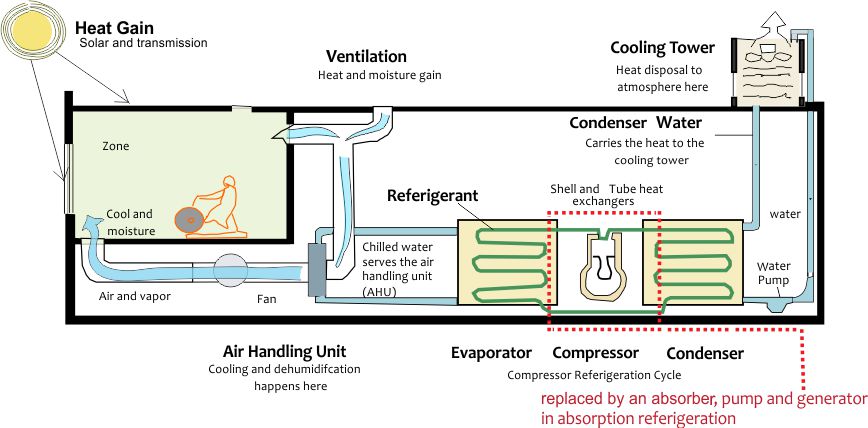

Central air conditioners are air conditioning systems designed for large buildings with complex operational requirement and varying schedules. The system has chillers to cool the water which is then transported to all air handling units which operates as per the space requirement and varies its speed & output accordingly. They are serviced by outdoor condensers that may be air or water cooled (cooling towers). Central air conditioners are more efficient compared to its peers. Moreover, they are quiet and secluded. These systems have higher capital costs compared to others but operational costs are significantly lower due to better system energy efficiency. However, these are complex systems that need plenty of installation space as well as regular and dedicated maintenance.

High efficiency chillers

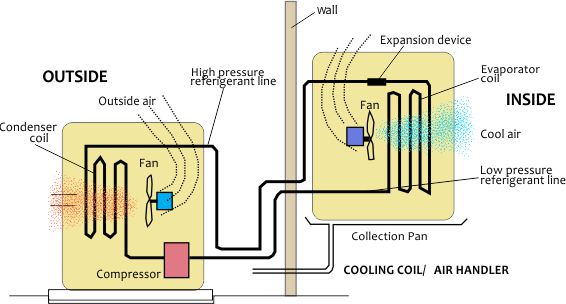

Chillers are the key component for cooling in a central system to work as a packaged vapour compression cooling machine. It is designed to either reject heat to condenser water (water cooled system) or to ambient air (air cooled system). Based on the technologies, 4 major categories of chillers are available in the market – screw, scroll, reciprocating, and centrifugal. Selection is made based on the initial cost, functional use, size of the cooling requirement, and energy efficiency potential. For a net zero energy building, efforts should be made to select equipment that exceeds the efficiency requirements of ECBC.

Chilled water system supporting components

Chilled water system is a complex system with many supporting components like primary and secondary, pumps, cooling tower, fans, variable frequency drives, controls etc. The overall efficiency of a chilled water system is a resultant of a combined performance of all these equipment, commonly known as system efficiency. Detailed discussion on the advantages and disadvantages of each component should be done for best selection, optimized size, and maximum energy efficiency.

Economizers

Heat generation through internal sources like equipment, occupants, lighting etc adds to the internal heat gains and increases the cooling requirement. In an event when the external air is cooler than the internal air, the external air could directly be used to meet the cooling requirement of the space. Many climatic zones like cold climate, composite climate, and temperate climate support the use economizers for a significant amount of days in a year. Designer should analyze the weather file and minimize the energy use with the application of an economizer. Two types of economizers are available in the market – air side and water side. Detailed discussion on the advantages and disadvantages of each component should be done for best selection, optimized size, and maximum energy efficiency.